In today's globalised environment, it is necessary to transport commodities over long distances. The most commonly moved commodities are fossil fuels, i.e. oil and petroleum products, gas, etc. The most efficient way to move these commodities is through 'product pipelines', i.e. oil and gas pipelines in the form of large capacity pipelines buried in the ground. The pipelines are usually made of steel and, even if protected by an insulation layer, this can be locally damaged, leading to corrosion of the pipelines in wet soil and, consequently, to the risk of fatal accidents.

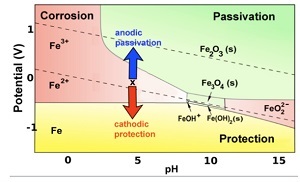

In order to prevent corrosion of steel pipes, various electrochemical properties of iron in different environments are used, defined by the electrochemical stability  diagram of iron (the so called Pourbaix diagram).

diagram of iron (the so called Pourbaix diagram).

From the diagram we can determine that if the electrical potential of the protected object made from iron (in our case a pipe) can be permanently kept at minus 0.7 V below the level of the surrounding environment, the iron will behave in a stable manner and become not subject to corrosion even in a humid environment.

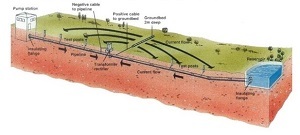

This method of corrosion protection is called "cathodic protection" because the protected object  essentially becomes the cathode of an artificially created galvanic cell. In practice, this protection is provided by an automatic DC power system, one pole (negative) of which is connected to the protected object (the pipe) and the other pole (positive) is introduced in the form of an anode rod into the soil surrounding the pipe.

essentially becomes the cathode of an artificially created galvanic cell. In practice, this protection is provided by an automatic DC power system, one pole (negative) of which is connected to the protected object (the pipe) and the other pole (positive) is introduced in the form of an anode rod into the soil surrounding the pipe.

A controller then keeps the voltage potential of the pipe below -0.7 V thus protecting it from corrosion. However, this implies a permanent supply of a definite amount of electricity to this system, i.e., a certain operating cost.

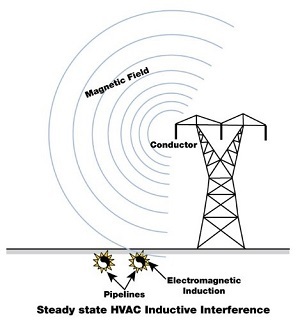

The situation will then worsen drastically in areas where high-voltage lines are located near the protected pipeline (or other steel component).  Magnetic fields created during the operation of the HV line induce secondary AC voltage in the nearby pipeline, which is superimposed on the already mentioned DC voltage of the cathodic protection.

Magnetic fields created during the operation of the HV line induce secondary AC voltage in the nearby pipeline, which is superimposed on the already mentioned DC voltage of the cathodic protection.

In the better case, this means that the automatic regulation of the pipeline voltage potential will require considerably more energy to compensate for the changes in the pipeline's electrical potential caused by the induced AC voltage, i.e. significantly higher operating costs; in the worse case, when the superimposed AC currents reach a level that cannot be compensated for, rapid corrosion of the pipeline, its perforation and collapse will occur.

Both manifestations of this undesirable phenomenon are sufficient enough to justify measures to remedy the situation.

The solution consists in the use of a special electrical filter that selectively removes the induced AC component from the affected piping and returns the cathodic protection function to its standard state of maximum efficiency (in terms of electric potential and costs).

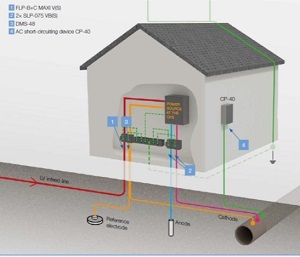

SALTEK offers this filter under the name CP-40-BOX. By installing the filter in the cathodic protection system, safe operation of the cathodic protection can be achieved (eliminating the risk of corrosion) and at the same time, significant financial cost savings can be made during the system´s operation. Also, the CP-40-BOX is supplemented with surge protection against direct and indirect lightning strikes, which protects not only the filter itself but also the entire electrical part of the cathodic protection against damaging caused by voltage surges.

The CP-40-BOX can also be easily connected to an already existing cathodic protection system, where it is able to eliminate AC induced currents of a peak value of 40A! Its installation means safe operation of pipelines, especially in areas where pipelines cross or coincide with power distribution lines, AC electrified railway lines or other potential sources of AC currents induced into the pipeline.

Apart from the CP-40-BOX filter, other parts of the cathodic protection system need also be protected against overvoltages, as shown in the following figure. You can find the relevant protection elements on the SALTEK website or in the SALTEK  product catalogue, or you may also contact our experts.

product catalogue, or you may also contact our experts.